Sizing Guides, Charts & Resources

Sizing Guides, Charts & Resources

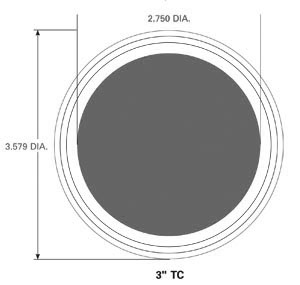

Sanitary Fittings Sizing Guide

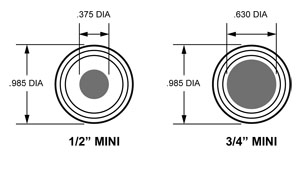

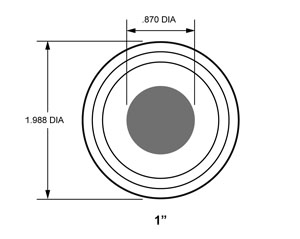

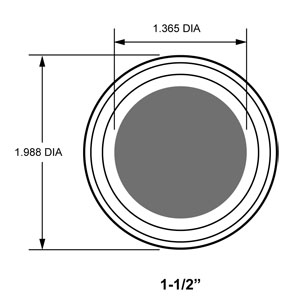

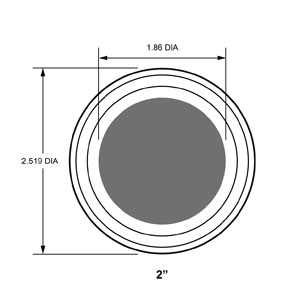

These actual size drawings are provided to eliminate sizing errors when specifying sanitary fittings.

The outside diameter is the same for 1/8", 1/4", 3/8", 1/2" and 3/4" I.D., “mini” sizes (.0992 O.D.).

The same holds true for the 1" and 1-1/2" I.D. sizes(1.984" O.D.). The 2", 2-1/2" and 3" I.D. have specific O.D. diameters.

For your convenience and ordering accuracy, all of these drawings may be used as sizing, I.D. and O.D. patterns.

For 4" (not pictured): 3.75" ID and 4.675" OD

SAE Dash Size Chart

| Nom SAE Dash Size | Nom Tube O.D. Inch |

| -2 | 1/8" |

| -3 | 3/16" |

| -4 | 1/16" |

| -5 | 5/16" |

| -6 | 3/8" |

| -8 | 1/2" |

| -10 | 5/8" |

| -12 | 3/4" |

| -14 | 7/8" |

| -16 | 1" |

| -20 | 1-1/4" |

| -24 | 1-1/2" |

| -32 | 2" |

| Back to top |

Technical Data 150 PSI Threaded Stainless Steel Fittings

Dimensions to ANSI 16.3;

Pressure to ANSI 16.5 Class 150LB-

Material ASTM A351 CF8 AISI304 or ASTM A351 CF8M AISI316

| Pipe Size (inches) |

Threads per Inch ( TPI- Pitch) | Nominal Outside Pipe Diameter OD (inches) |

| 1/16" | 27 | 0.313 |

| 1/8" | 27 | 0.405 |

| 1/4" | 18 | 0.54 |

| 3/8" | 18 | 0.675 |

| 1/2" | 14 | 0.84 |

| 3/4" | 14 | 1.05 |

| 1" | 11-1/2 | 1.315 |

| 1-1/4" | 11-1/2 | 1.66 |

| 1-1/2" | 11-1/2 | 1.9 |

| 2" | 11-1/2 | 2.375 |

| 2-1/2" | 8 | 2.875 |

| 3" | 8 | 3.5 |

| 3-1/2" | 8 | 4 |

| 4" | 8 | 4.5 |

| 4-1/2" | 8 | 5 |

| 5" | 8 | 5.563 |

| 6" | 8 | 6.625 |

| 8" | 8 | 8.625 |

| 10" | 8 | 10.75 |

| 12" | 8 | 12.75 |

| 14" | 8 | 14 |

| 16" | 8 | 16 |

| Back to top |

What are the Benefits of Electropolishing?

Electropolishing is the greatest form of passivation on stainless steel. Electropolishing removes surface metal by attacking high points on the surface. This process makes the surface smoother while eliminating contaminants which results in a clean and sterile surface. Electropolishing is intended to reduce corrosion and extend the life of the product. Food and beverage process equipment, tubing and pipe, medical equipment, and heat exchangers are just a few of the products that benefit from electropolishing. The smoother surface finish derived from the electropolishing process will naturally reduce the collection of processed materials and contaminants on the product contact surfaces.

The equipment will clean faster and more effectively using a smaller volume of cleaning products. It saves downtime expenses, cleaning materials, and disposal of cleaning products if environmentally controlled near your facility. After electropolishing, the appearance of the surface finish is a bright and smooth polish with a great light reflection showing the clarity of the item.

Although the better physical appearance is pleasant to view, the more important benefit is the corrosion resistance. Corrosion resistance is created by the passive layer created on the surface of the metal from the electropolishing process. Free iron is removed from the surface of the metal. If you have any questions about electropolishing please contact us.